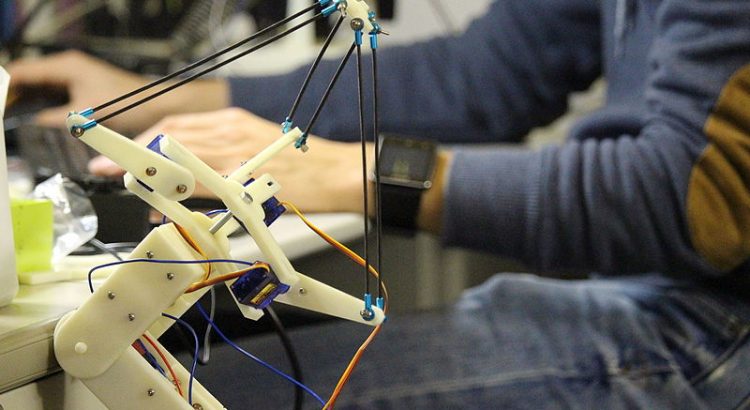

What do you think when you hear the word ‘robot’? Most robots use biomimicry to ape the actions of a human or animal skeleton, but not the delta robot. Designed to be purely functional, the design of this efficient and optimised machine is inspired by maths rather than nature.

From chocolates to engines

Delta-type robots first emerged in the food industry. Their simple pick and place movements proved ideal for packaging delicate chocolates – by using four degrees of freedom, including rotation around a vertical axis, the delta robot could achieve precise high-speed, low-payload automation.

The first prototype of the delta robot followed in 1986. Where once manufacturers were dubious about these umbrella-shaped machines, they are now recognised as being unparalleled for sorting, pick and place, and high speed/low mass operations.

Delta robots are currently used for a range of functions, including dispensing glues; for example, the robot dispenses metal bonding adhesive. They are now commonplace throughout the automotive industry, and they still pack chocolates!

Delta robots in the field

Although delta robots are unparalleled at the tasks they perform, they are not without issues. With acceleration up to 12-15 g, a delta robot needs enough gripping power not to decelerate and send its products flying.

Some products can’t be gripped by using vacuum suction, necessitating the use of mechanical grippers. Unfortunately, such devices add weight, which then reduces capacity. Getting the design right for your application is crucial for ultimate success with this type of automation.

Why use delta robots?

Delta robots are custom designed to meet the needs of the job rather than using biomimicry. A delta robot easily outperforms a robot arm when it comes to executing pick and place operations.

As production lines get ever-faster, the delta robot has a real mechanical advantage in terms of flexibility and performance. If you have a workflow rate that needs to be sustained along the line, delta robots are the obvious choice.

Where other fast robots can suffer motor burnout, the design of the delta means the engine is easy to maintain and to enclose; in addition, their speed and accuracy mean a delta can be used to perform a wide range of tasks that robot arms can’t match. This umbrella-shaped automaton is the future for pick and place assembly lines.